100kW Mobile Charging Unit

Since 2020, Next Generation Machinery B.V. (NGM) has been focusing on making heavy machinery more sustainable. To this end, we have set ourselves an ultimate goal: to develop a robust zero-emission power source that can be built into heavy machinery as a practical and economically viable alternative to the diesel engine.

In the switch to emission-free construction, there is already a transition to electrification of construction equipment. The question here is how the batteries of this heavy machinery can be charged efficiently (cost efficiently) at a time when a grid connection is not always available due to grid congestion. This requires off-grid charging solutions. This is what NGM is now working on with the development of a 100kW mobile charging unit. The basis of this mission is a source of power, with which we want to lay the foundation for achieving our ultimate goal. We are applying this power source in a concrete solution to the problems in, among other things, construction with the working name MOOSE: Mobile Origination of Off-grid Sustainable Energy

Advantages

The MCU does not emit any nitrogen oxides (NOx) or particulate matter. The conversion of hydrogen into electric power in a fuel cell always releases water (vapor) and because methanol consists of a C atom, CO2 is also released applying our technology. CO2 however is not a local problem (due to precipitation such as nitrogen oxides) and moreover, this CO2 is not fossil due to the use of green methanol, because it is part of a short cycle. In other words, no net CO2 is added to the atmosphere. As a result, our technology is qualified as completely Zero-Emission. Therefore, the MCU offers a solution without restrictions for emission-free (construction) projects and in particular for projects in nitrogen-sensitive areas.

In addition to the benefits in terms of emissions, the MCU is quiet. Noise nuisance from humming diesel generators or other combustion engines is a burden of the past. Due to the logistical advantages that methanol offers through its energy density, it also does not result in a significant increase in heavy traffic around a construction site.

Want to know more? Contact us!

Specifications 100kW Mobile Charging Unit

Power and output:

- Fuel cell continuous power output: 100 kW

- Internal battery capacity: ~60 kWh (optional extra capacity)

- DC Charging System:

- Plug: 2 x CCS2 70kW (optionally expandable to 140kW, max 4 plugs)

- Voltage range: 200-1000V DC

- Current max 220A (optional 440A)

- AC Output (Optional):

- 100kW, 50/60Hz, 400V

- Sockets: 1x CEE – 16a 1F/N, 1x CEE – 16a 3F/N, 1x CEE – 32a 3F/N (optional custom configurations possible)

Dimensions and weight:

- Weight: ~ 3,000 kg

- Dimensions (LxWxH): 2,450 mm x 1,750 mm x 2,000 mm

The MCU is equipped with a central lifting point, lashing eyes on 4 corners and forklift pockets on the long side.

General and operational:

- Connectivity & telemetry

- Operating temperature (min/max): -20ºC / +45ºC

- Tilting angle: 15º max

- Operational Life: ~30,000 hours

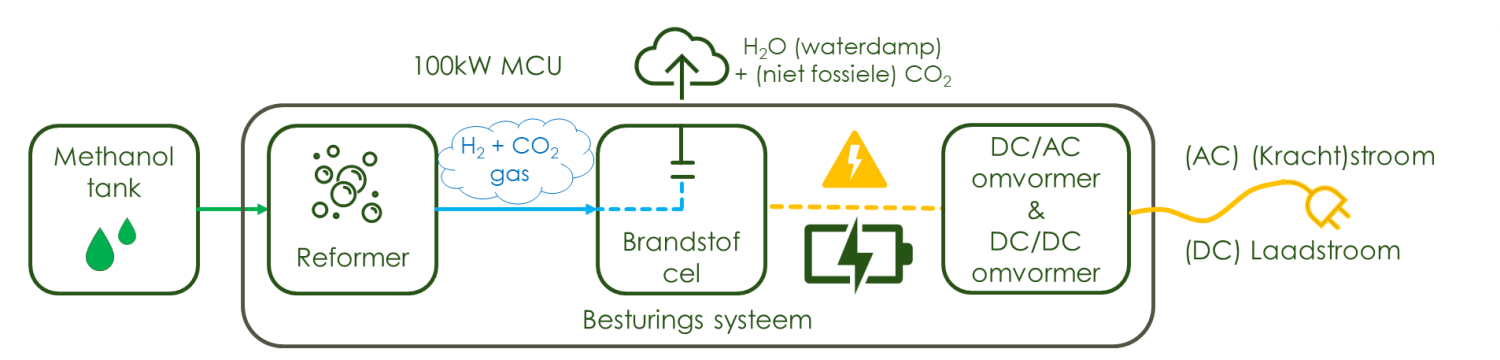

Mobile Charging Unit technology

Energy at the touch of a button

The generator has a clear user interface that enables the installation at the touch of a button. Power is immediately available from the internal battery pack, so the work can be started immediately! The reformer and fuel cell are now preheated. As soon as the fuel cell is at working temperature, the battery pack is recharged.

NGM Fuel Cell Generator functionality

Green methanol (Bio- and/or E-methanol) is converted into a hydrogen-rich gas within a so-called reformer. In the fuel cell, this gas mixture is converted into water vapor and a DC current, which is immediately available at the outlet, but is also used to recharge the internal battery pack. The direct current generated by this can be used directly as DC charging current or, for example, converted into 3-phase 400V three-phase power current by means of inverters.

Flexibility

By increasing the capacity of the battery pack and/or the inverters, much more power can be supplied in a short period of time. This could be achieved both internally and externally. We are happy to help you make an inventory of your project and provide advice without obligation regarding an optimal system choice that meets the expected energy needs.