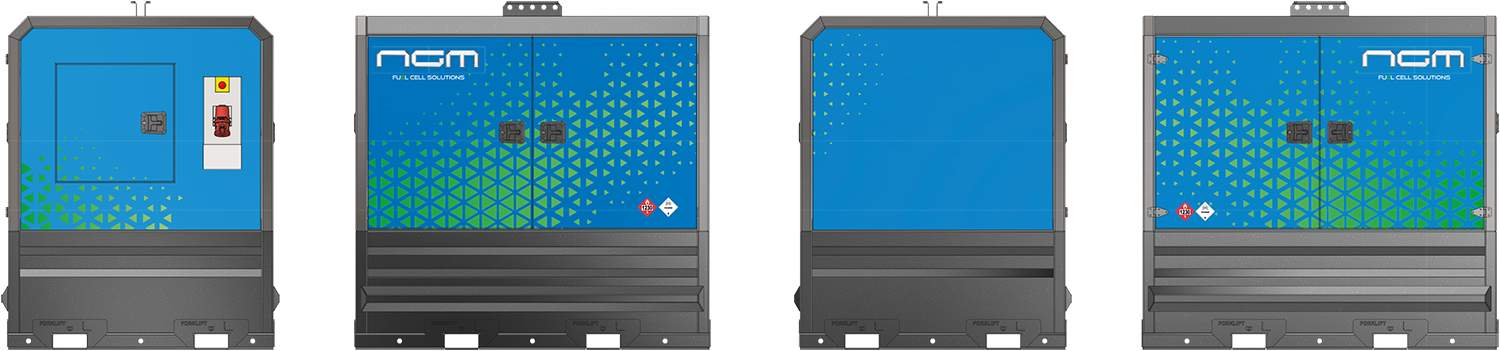

NGM Fuel Cell Generator

Construction sites are big power consumers. There are power tools, pumps are running and the shack needs power. In the future, power needs will only increase. Cars and (heavy) equipment will then be electrically powered and will need to be recharged daily at the construction site. Without a fixed power connection, mostly diesel generators are currently used to supply the construction site with the necessary power.

As possible clean alternatives, mobile battery systems and hydrogen fuel cell systems are on the market. The disadvantage of these solutions is that they involve either a large transport volume or a high transport weight. This increases the number of transport movements and thus overall emissions and nuisances.

Next Generation Machinery has developed a generator where the energy is supplied in the form of methanol as a renewable energy carrier.

Why methanol?

- Methanol is not under pressure and is liquid. This allows it to be easily transported

- Methanol can be produced from many renewable sources, including biomass, non-recyclable waste, wind and solar energy

- Production is scalable

- Methanol is liquid, making it easy to transport

- Methanol has a high energy density of over1 kWh per liter

- A (tank) infrastructure can be established at low cost

Proposal?

Want to request a quote or learn more about the NGM Blue Box? Contact us. We will be very happy to make time to explain the many benefits to you. Because together we need to make our world sustainable as soon as possible.

Power specifications

The Fuel Cell Generator has the following specifications:

- Fuel cell continuous power: 4.5 – 13.5 kW. Optionally, other configurations are possible

- Battery capacity: 10-40 kWh

- Inverter continuous output: 9.5 kVA – 42 kVA – 3-phase

- Connection: 16A CEE wall outlet for the lightest model. 63A CEE wall outlet for the heaviest model.

- Optionally, other configurations are possible

- Energy carrier: bio-methanol/ demineralized water mix (60%/40%)

- Tank capacity: 900 liters (=1,000kWh)

- Weight: 1,560 kg (dry) – 2,485 kg (wet) for the lightest model. 2,000 kg (dry) – 2,925 kg (wet) for the heaviest model

- Dimensions: 1,860 mm x 1,410 mm x 1,700 mm

- Lifting point: Included

- Lashing eyes: Included

- Forklift pockets: Lengthwise and widthwise

- 4G communication: optional

- GPS positioning: optional

- Dynamic control for well or pump: optional

- Charging point with type 2 connector: optional

- External tank (+ 1,000/ 1,500 kWh): optional

Operation of generator

Energy with one push of the button

The generator has a clear user interface that turns the system on at the push of a button. Power is immediately available from the internal battery pack, so operations can be started immediately! Meanwhile, the reformer and fuel cell are preheated. Once the fuel cell reaches operating temperature, the battery pack is recharged.

Operation NGM Fuel Cell Generator

In a more detailed explanation, the operation consists of a few steps. The generator has an internal tank that can be refilled. Or an external tank can be connected. The tank is filled with a mix of 60% renewable methanol and 40% demineralized water. This is supplied as a pre-mix. The methanol is first converted into hydrogen and CO2 in a so-called reformer. The CO2 is not fossil and is part of a short cycle. It disappears into the atmosphere through an exhaust. The hydrogen is converted into water vapor and electricity in a fuel cell. This can be used to charge the internal battery pack. The inverters can convert this direct current into 3-phase 400V power.

Modular system

The system is modular in design. By increasing the number of fuel cells, higher power can be delivered for a long period of time. By increasing the battery pack and inverters, much more power can be delivered in a short period of time. This is useful when there are many consumers simultaneously or when electric motors or pumps are started up, for example.

Whisper quiet

The generator is whisper quiet. Noise pollution from diesel generators or pumps is thus a thing of the past. When work is being done in residential areas on sewers, for example, the pumps can run day and night without disturbing the sleep of local residents.

No emission of nitrogen oxides

In addition to the absence of noise emissions, the generator emits no nitrogen oxides (Nox). This makes the sustainable power part of the solution to allow (construction) projects in nitrogen-sensitive areas to go ahead.